Understanding Laser Cutting for Glass Sheets

How Laser Technology Interacts with Glass Materials

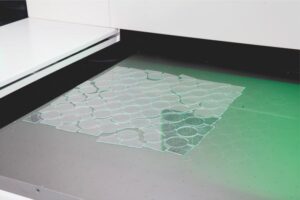

Laser cutting technology is becoming increasingly popular for processing glass sheets. It offers high precision and avoids direct contact. Traditional methods often cause damage, but laser cutting machines guide a focused beam of heat along a predetermined path. This creates small, controlled fractures, allowing the glass to split cleanly. This method is suitable for delicate materials such as soda-lime, borosilicate, and laminated glass. However, each type of glass behaves differently depending on its composition and how it handles heat.

This non-contact tool, designed for glass substrates, particularly thin, fragile, or uneven ones, utilizes a combination of laser marking and mechanical fracturing. It carefully cuts and marks the glass along a designated path. Then, it performs a complete break in a single operation on a machine. No additional edge polishing or subsequent work is required.

This non-contact method reduces physical stress. Therefore, laser cutting is suitable for sensitive tasks in the electronics and optics industries.

Advantages of Using a Glass Laser Cutting Machine

The main benefit of a glass laser cutting machine is its skill in making exact cuts. It avoids chips or breaks. Detailed shapes and complex designs come out with strong accuracy. This meets many creative demands.

The main advantage of glass laser cutting machines is their precise cutting capabilities. They avoid chipping or breakage. Intricate shapes and complex designs can be cut with high accuracy. This meets many creative needs.

Laser systems also reduce waste by strictly following the contours. These systems are fast for both home projects and factory operations. These tools have many automated features that can handle the demanding requirements of glass processing.

Choosing the Right Glass Laser Cutting Machine

The glass laser cutting machine developed by BLM Automatic Machine is a non-contact, high-precision processing system specifically designed for glass substrates, especially fragile, ultra-thin, and irregularly shaped glass materials.

Based on a collaborative “laser marking + mechanical fracturing” technology, this equipment can precisely mark the cutting path and achieve clean, single-pass fracturing on a single machine, without the need for subsequent edge grinding or secondary processing.

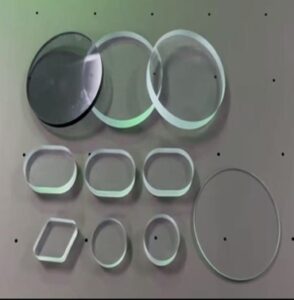

It is widely applied in the efficient forming and deep processing of:

- Electronic glass (OLED display screens, cover glass for consumer electronics)

- Photovoltaic glass

- Automotive glass

- Special optical glass

Core Advantages

- Integrated cutting and crushing process

- High precision, high efficiency, and high-quality processing

- Fast cutting speed with excellent edge quality

- Environmentally friendly and consumable-free

- High degree of automation and intelligent control

Technical Specifications

- Laser source:Infrared laser

- Glass thickness capacity:1 – 20 mm

- Working area:1000 × 800 mm

- Cutting speed:Up to 800 mm/s (2 mm glass)

- Processing accuracy:≤ 0.02 mm

- Machine dimensions:2600 × 2200 × 2300 mm

- Total weight:3500 kg

- Power requirement:12 kW

Although many users search for a tempered glass laser cutter, it should be clearly noted that tempered glass cannot be laser-cut directly due to its internal stress structure. The equipment is mainly used for:

- Surface marking and engraving

- Pre-cut tempered glass secondary processing

- Annealed or laminated glass full cutting

Considerations When Working with Tempered Glass and Lasers

Why Tempered Glass Is Challenging to Cut with Lasers

When a laser generates intense heat, the glass tends to shatter completely rather than splitting smoothly.

The inner tension in tempered glass leads to shattering on laser touch. For this reason, usual laser cutting methods do not fit tempered glass.

Alternative solutions for tempered glass projects

Rather than slicing tempered glass straight away:

- Use pre-cut tempered glass and add low-power marking for logos or patterns.

- Opt for annealed or laminated glass in projects that need complete cuts. These options absorblaser heat better without total failure.

Defining the functions of home or commercial laser cutting setups

Basic Components of a Reliable Setup

High-Stability Frame Construction

The sturdy frame reduces vibrations during running. This leads to improved accuracy.

Adjustable Bed Height and Pass-through Doors

Such options allow fitting various sizes and depths of glass sheets.

Integrated Exhaust System and Air Assist

These parts are key to safety and clean results. The systems clear the smoke and bits from cutting. This matters a lot with coated or sticky-backed glass.

Software Compatibility and Workflow Integration

User-Friendly Interfaces

Touchscreen or computer setups make running the machine simple. These setups cut down on prep time.

Design Software Support

Check for fit with tools like CorelDRAW, AutoCAD, or LightBurn. This ensures a smooth workflow.

Safety Measures in Operating a Glass Laser Cutter

Built-in Safety Features to Look For

Enclosed Work Area with Interlock Systems

These guards protect users from sudden exposure to strong beams while the machine works.

Emergency Stop Buttons and Fire Sensors

These setups let you halt everything fast if heat builds up or parts fail.

Best Practices for Safe Operation at Home or Worksite

Always use eyewear that matches the laser’s light type. Good airflow is vital when working on coated or painted areas. It prevents breathing in harmful vapors.

Maintenance Tips to Prolong the Life of Your Glass Laser Cutter

Applications of Laser-Cut Glass Sheets in Various Settings

Home-Based Projects Using Laser Cut Glass Sheets

Custom Decorative Panels and Mirrors

These sharp markers allow people to add a personal touch to items in their home, such as mirrors or wall decorations.

DIY Lighting Fixtures

Laser-cut frosted covers bring style and use to homemade light setups, and laser cutting glass sheet technology makes it easier to achieve consistent diffusion effects and refined edge quality.

Business Applications Across Industries

Architectural Installations

Laser cutting serves many fields, including home appliances, electronics, building and decor, cars, solar power, health, and research.

Tailored layered panels appear often in business spaces, signs, and room dividers.

Product Packaging and Branding

Logos and markings on cosmetic containers or branded products can increase product value and brand recognition.

FAQ

Q: Can a laser cutter cut tempered glass?

A: No, tempered glass, due to its internal stress structure, will usually shatter under laser heat. It is recommended to use pre-cut tempered glass and only engrave with low power settings.

Q: What type of laser is best for cutting glass sheets?

A: Infrared lasers are commonly used for cutting standard glass sheets, such as soda-lime or borosilicate glass, providing precise control and minimal edge chipping.

Q: Is it possible to customize a laser cutting system for specific industrial needs?

A:Yes. It can also customize non-standard glass deep processing production lines to meet the glass processing needs of different industries such as electronics, construction, and new energy. BLM Automatic Machine provides customized equipment solutions based on specific requirements.

Q: What thicknesses can be processed with a typical industrial glass laser cutter?

A:It can process glass with a thickness between 0.1 and 20 millimeters. Depending on the machine model and power level, thicker materials may require multiple passes or special processing.

Q: What industries benefit most from using laser-cut glass?

A: Industries such as architecture, consumer electronics (such as OLED displays), automotive, solar energy (photovoltaics), and medical devices all benefit from the precision of laser cutting in terms of both aesthetics and performance.