Overview of Modern Glass Drilling Technology

What is Glass Drilling Technology

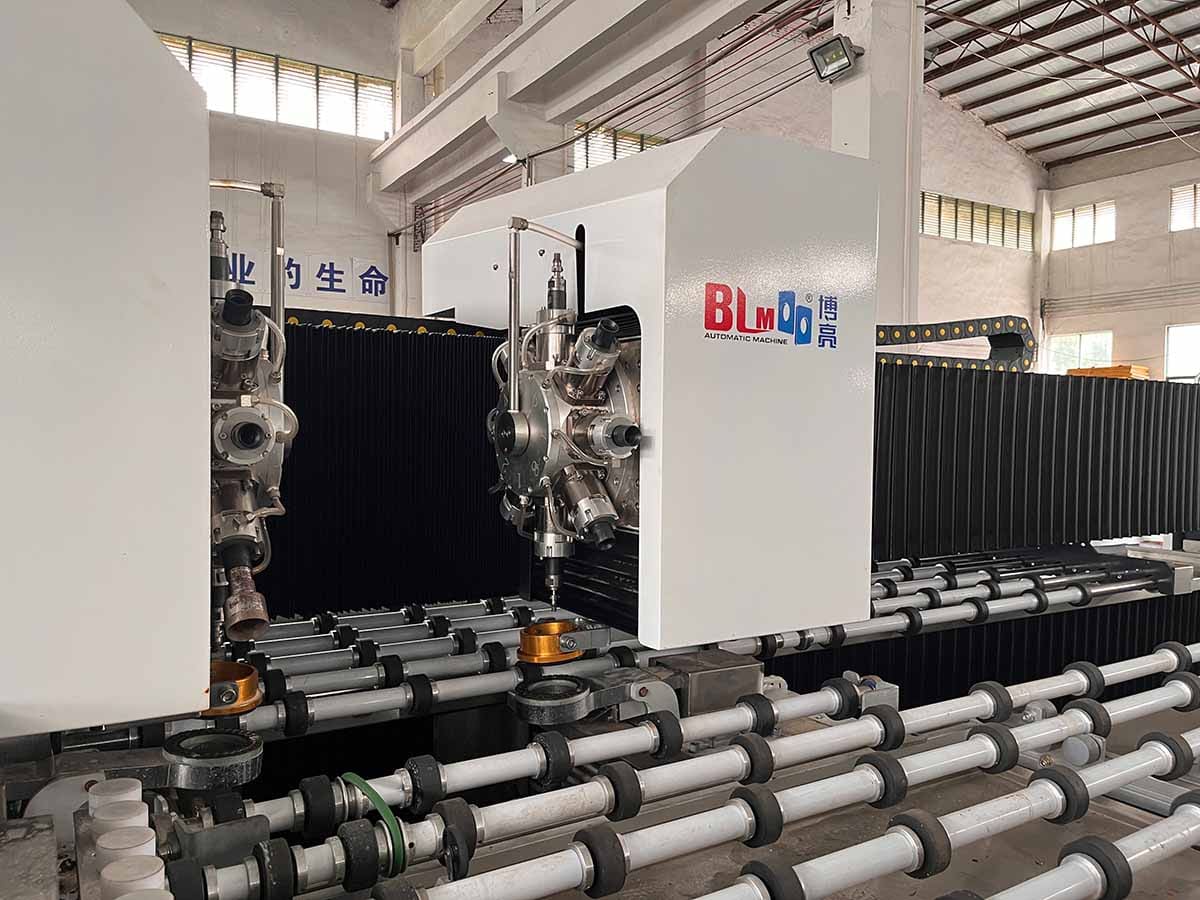

Glass drilling technology refers to the specialized method of creating precise holes in glass substrates using high-precision equipment and tools. The equipment it used employs various spindle configurations, advanced CNC systems, and optimized drill bits to ensure consistent hole diameter and positioning accuracy.The equipment features a high level of automation and is capable of efficiently and continuously completing architectural glass drilling operations

The Role of Glass Drilling Technology in Modern Glass Deep Processing

Glass drilling plays a critical role in enhancing the structural integrity and functional customization of processed glass. It enables precision manufacturing in sectors such as construction, electronics, and automotive by delivering repeatable and accurate hole-making for mounting, ventilation, or aesthetic purposes.

With its automated and high-precision characteristics, it meets the efficient and precise requirements of the glass processing industry for the drilling process, helping enterprises achieve intelligent production upgrading in the glass drilling process.

Overview of Modern Glass Milling Technology

What is Glass Milling Technology

Glass milling technology involves the removal of material from glass surfaces using rotary cutters to create slots, shapes, or surface textures. It is often integrated with drilling and polishing functions in multi-functional machines.

A milling cutter function can be optionally configured to realize the combination of drilling, milling and polishing.

The Role of Glass Milling Technology in Modern Glass Deep Processing

Glass milling enhances design flexibility by enabling customized shaping and surface patterning. It is essential for producing intricate glass components used in decorative architecture, appliance panels, and electronic displays.

Can Milling Technology Be Used for Drilling?

While primarily intended for shaping and surface finishing, modern glass milling machines can also perform drilling tasks when equipped with the appropriate bits and CNC programming.

The rotating positioning accuracy of the tool magazine is high, ensuring the positional accuracy when switching drill bits, thereby ensuring the drilling accuracy of each hole diameter.

Comparison of Glass Drilling Technology and Milling Technology

|

Feature |

Glass Drilling Technology |

Glass Milling Technology |

|

Primary Function |

Hole creation |

Surface shaping |

|

Tool Type |

Drill bits |

Rotary cutters |

|

Typical Diameter Range |

Φ6–Φ50mm |

Custom geometries |

|

Material Removal Method |

Axial pressure |

Lateral motion |

|

Common Applications |

Mounting holes, venting |

Decorative patterns, slots |

|

Integration Potential |

High with CNC & ERP |

Often integrated with drilling |

|

Automation Level |

High |

High |

Key Processes for Achieving High Precision in Glass Drilling and Milling

Key Technologies in Precision Glass Processing

- The Application of CNC Technology

With the automatic control of the CNC system, it can continuously complete drilling operations with different hole diameters, greatly improving processing efficiency. This ensures high precision glass drilling during processing.

- The Impact of High Rigidity Machine Frames on Drilling Precision

The rack undergoes welding, annealing, gantry milling, sandblasting, rust removal, and painting processes to ensure that the equipment is not easily deformed during long-term use and to ensure equipment accuracy.

Key Factors Affecting Glass Drilling and Milling Precision

- The Reasonable Matching of Spindle Speed and Feed Rate

Optimal pairing of spindle speed (up to 12000rpm) and feed rate ensures clean edges without cracking or chipping.

- The Impact of Stable Clamping and Positioning on Processing Quality

Stable clamping and precise positioning technologies are essential to avoid misalignment that may affect hole location accuracy or create stress on the glass substrate.

Auxiliary Technologies for Precision Glass Processing

- The Role of Cooling and Lubrication Systems in Precision Processing

The oil circuit automatically pumps oil, which can be filled regularly and quantitatively to ensure the lubrication of each component. Proper lubrication minimizes tool wear and thermal expansion during extended operations.

Precision Control Methods in Glass Processing

- Stable Clamping and Precise Positioning Technologies

Using the limit switch on the input and output table, there will be no misoperation signal when there is water on the glass surface.

Innovative Development of Glass Drilling and Milling Technologies

Multi-Spindle Synchronous Processing Technology

This technology is suitable for batch/scattered production scenarios. It is suitable for batch/scattered production scenarios of multi-specification glass drilling and milling technology, which enables both precision drilling and milling of glass with high efficiency and accuracy.

Digital Applications of Online Drawing and Scanning Processing

Take Glass Drilling & Milling & Polishing Machine A98 (Spindle8+8) as an example, the operation interface of this equipment is an industrial computer, which can be used for online drawing. It is matched with a barcode scanner to read information online via barcode, automatically distribute and drill holes.

Integration Trends of ERP Systems and CNC Equipment

|

Drawing Input |

Manual |

Online drawing via barcode |

|

Scheduling |

Offline/manual |

ERP-driven real-time updates |

|

Fault Diagnosis |

Manual check |

Automatic alarm display |

|

Operation Interface |

Basic console |

Industrial computer with HMI |

BLM Automatic Machine’s Glass Drilling & Milling & Polishing Machine A98 (Spindle8+8) integrates glass drilling, milling and polishing functions. It can be equipped with 16 types of drill bits simultaneously, making it suitable for multi-functional deep processing of architectural glass, decorative glass, etc.

Safety Considerations When Working with Glass Processing Equipment

Safety Protection via Automatic Limiters and Sensor Systems

Safety sensors detect anomalies like misalignment or foreign objects on glass surfaces. Limit switches help halt operations instantly to avoid damage or injury.

Electrical Control Systems that Meet CE Standards

BLM Automatic Machine ensures international safety compliance. This product has passed the CE certification standard;Every electrical component has a clear identification, and the electrical components on the corresponding machines facilitate after-sales maintenance.

Automation Designs to Reduce Risks in Manual Operations

Automation reduces manual handling risks by performing repetitive tasks under controlled conditions. The use of barcode scanning and automatic tool changes further minimises human intervention.

Maintenance and Calibration of Precision Glass Tools

The Role of Automatic Lubrication Systems in Equipment Maintenance

Automated oil circuits ensure consistent lubrication across moving parts, which reduces wear. The oil circuit automatically pumps oil, which can be filled regularly and quantitatively to ensure the lubrication of each component.

The Significance of Regular Calibration for Processing Precision

Calibration ensures that all axes operate within defined tolerances. Periodic checks are crucial, especially for customized equipment working across variable formats.

The Value of Industrial Control Systems in Fault Diagnosis

Modern CNC systems display real-time feedback, including error messages and alarm signals. Each moving part can be controlled separately through the manual operation interface. It can display all input and output signal points and relevant alarm signals, which can be presented on the control interface for maintenance to judge the fault point.

If you’re interested in learning more about our glass processing equipment or would like to request a quote, please don’t hesitate to contact us. Our team is ready to provide you with detailed technical information and guide you on how BLM Automatic Machine’s advanced technology can enhance your production line.

FAQ

Q: What is glass milling technology used for?

A: Glass milling technology is used for cutting, shaping, polishing, and drilling operations in deep processing applications such as architectural glass, automotive panels, decorative items, and appliance glass.

Q: What makes high precision glass drilling different from standard methods?

A: High precision glass drilling uses CNC-controlled spindles, optimised feed rates, real-time digital drawings, and advanced clamping to achieve consistent results with micron-level accuracy.

Q: Can BLM Automatic Machine’s equipment be customized?

A: Yes. BLM Automatic Machine offers customised equipment that supports features like multi-spindle configurations, ERP system integration, barcode scanning functions, and optional milling cutter modules.

Q: How does barcode processing benefit glass manufacturing?

A: Barcode processing eliminates manual input errors by allowing machines to scan job codes directly from barcodes or QR codes for automated drawing import and drilling execution.

Q: What are typical usage scenarios for BLM Automatic Machine’s drilling & milling systems?

A: These systems are ideal for factories producing building façades, shower enclosures, furniture glass panels, or any application requiring multiple hole sizes or complex patterns across large-format sheets.