What is High Precision Glass Drilling Technology

Definition of High Precision Glass Drilling

High precision glass drilling refers to the ability to create holes in glass with exact diameters, minimal deviation in positioning, and exceptional edge quality. It emphasises two main aspects: hole diameter precision and positioning tolerance, as well as edge quality with controlled chipping.

The positioning accuracy of drilling machines is tested using professional equipment, ensuring tight tolerance control, which is crucial in sectors such as electronics and automotive glass. Chipping control is achieved through optimised drilling speeds and specialised drill bits. For instance, advantages of the new type of glass drill include sharpness, durability, wear resistance, small edge chipping, high efficiency, and fast speed.

Key Technological Standards for High Precision Drilling

Achieving such precision requires advanced standards including:

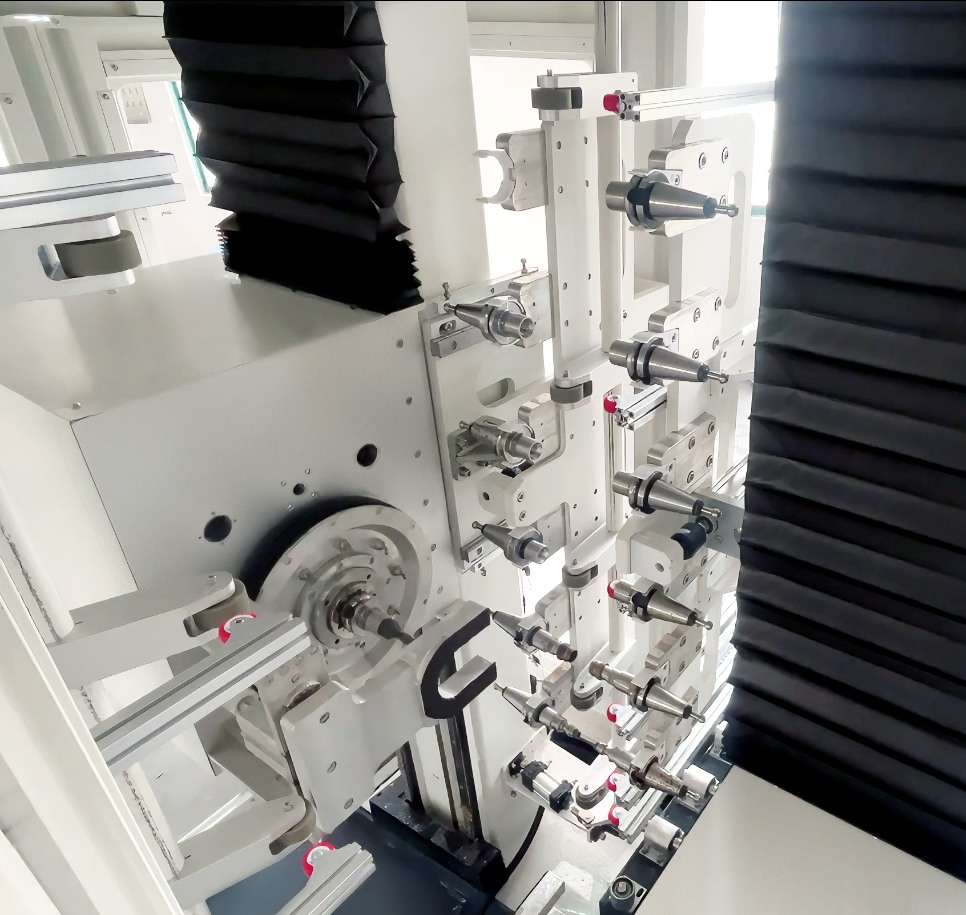

- CNC Positioning Accuracy: Rack and guide rail drive the precision of machine head movement control, ensuring minimal deviation during operation.

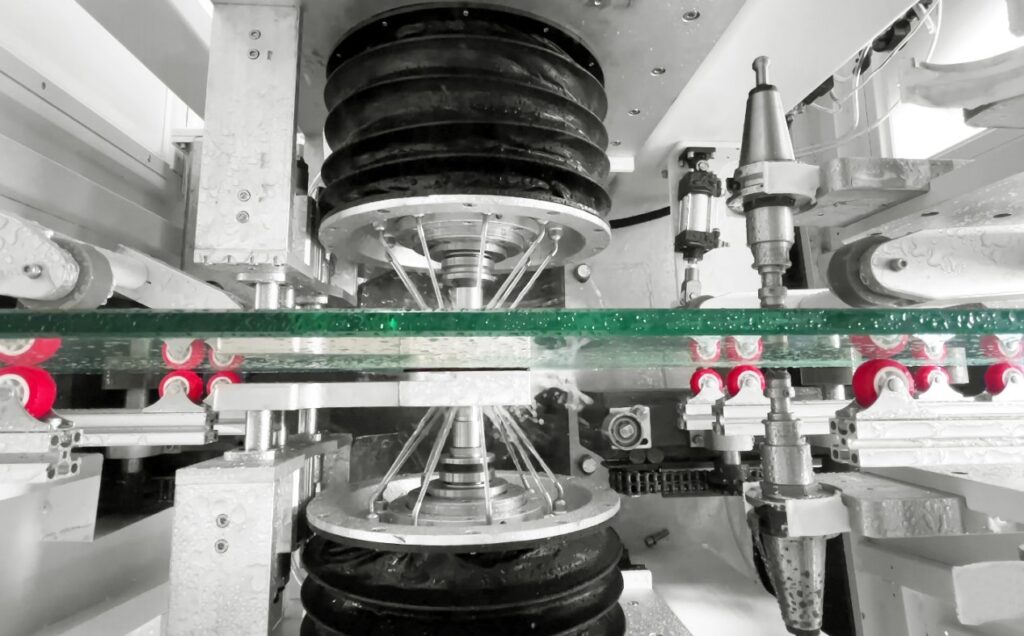

- Spindle Speed and Feed Control: High-speed spindles with rotation speeds up to 12,000 rpm allow for precise drilling, ensuring minimal glass breakage and enhancing overall drilling accuracy.

- Cooling and Lubrication Systems: The oil circuit automatically pumps oil, which can be filled regularly and quantitatively to ensure the lubrication of each component, which prolongs machine life and maintains performance.

From Manual to CNC: The Development of Glass Drilling Technology

Limitations of Traditional Manual Glass Drilling

Traditional manual glass drilling machines have several limitations:

- High Breakage Rate: Manual pressure inconsistencies often lead to cracks or complete breakage.

- Unstable Hole Quality: Hole drawing and glass moving are both manual operations, resulting in variable quality.

- High Labour Intensity: Operators are required to perform multiple tasks manually, increasing fatigue and reducing throughput.

Advantages of CNC Glass Drilling Technology

CNC-driven systems offer multiple advantages for glass drilling technology:

- Consistent Precision: Equipped with a numerical control system, it can achieve high-precision automated drilling.

- Automated Tool Control: The system enables automatic tool changes, supporting a variety of tool holder specifications. This allows for the installation of multiple drill bits with different diameters simultaneously, optimizing efficiency and reducing downtime during the drilling process.

- Suitable for Both Mass and Custom Production: Some machines can be used standalone or connected with edging machines, cleaning machines, etc., to form an automated production line.

How Automatic Glass Processing Enhances Drilling Quality and Efficiency

What is Automatic Glass Processing?

Automatic glass processing is a comprehensive workflow that integrates:

- Drilling, Milling, and Polishing: A seamless process combining drilling, milling, and polishing operations to enhance efficiency and precision in glass processing.

- Automatic Glass Transportation Systems: Place the glass on the roller of the input table for feeding. When the switch detects the glass, the suction cup will suck on the glass, and the glass will begin to move.

- Barcode Scanning and ERP Integration: Can read information through online barcode and automatically divide/drill holes; Can be integrated with ERP, online drawing and navigation.

Key Automated Features in Modern Glass Drilling Machines

Modern machines feature:

|

Feature |

Description |

|

Automatic Tool Change |

Automatic tool change reducing manual tool change time |

|

Online Drawing & CAD File Import |

Online drawing All parts of sport components can Individual control through manual operation interface |

|

Hole Position Allocation |

Automatically distributes and drills holes supports online barcode scanning |

These features enable seamless automatic glass processing with minimal human intervention.

Application of High-Precision Automatic Glass Drilling Technology

Building and Curtain Wall Glass

Drilling large glass panels requires high precision, especially for architectural applications where precise positioning is critical to meet structural and aesthetic requirements.

Shower and Furniture Glass

Applications like shower doors often involve multi-hole patterns, necessitating versatile systems capable of handling batch and small-batch production for different glass specifications.

Electronic and Automotive Glass

In the electronics and automotive industries, precision and consistency are essential. The drilling process must meet tight tolerances to ensure uniformity and reliability in high-volume production.

BLM Automatic Machine provides a comprehensive solution for high-precision glass drilling across various industries. With its vertical structure design, automated tool control, and CNC precision, it is ideal for processing large glass panels, multi-hole patterns, and high-volume production, ensuring both efficiency and consistency.

Key Considerations When Choosing Glass Drilling Technology

Glass Size, Thickness, and Hole Diameter Range

A key factor is compatibility with varying specifications:

|

Model |

Max Glass Size |

Hole Diameter |

Thickness |

|

A71X (2515) |

2500×1500mm |

φ6–φ50 |

4–19mm |

|

A71X (6030) |

6000×3000mm |

φ6–φ50 |

4–19mm |

|

A71X(4225) |

4200×2500mm |

φ6–φ50 |

4–19mm |

|

A71X(3020) |

3000×2000mm |

φ6–φ50 |

4–19mm |

A71X series equipment integrates glass drilling, milling and polishing functions, offering versatility from small to large-scale processing.Users can select according to their specific requirements.

Automation Level and Production Capacity

For high-throughput needs, automated production lines offer efficient and continuous processing, ensuring consistent quality and speed for large-scale glass drilling operations. For custom or smaller orders, standalone units provide flexibility, allowing for tailored adjustments and precise handling of varying production volumes and specifications.

Conclusion

Why Precision and Automation are Industry Standards

Glass processing industries demand high reliability, speed, and accuracy. The equipment with CNC-based systems like those by BLM Automatic Machine provide solutions that meet these standards with integrated automation—from barcode scanning to ERP connectivity.

Long-Term Benefits of High-Precision Automated Glass Drilling

Adopting automatic glass processing with high precision delivers:

- Reduced error rates

- Lower labour costs

- Enhanced product quality

- Scalability for future growth

In conclusion, high precision glass drilling technology is essential for meeting the demands of modern automated glass processing. It ensures accuracy, efficiency, and quality, driving innovation and productivity in the industry.

FAQ

Q: What makes high precision glass drilling essential in modern manufacturing?

A: It ensures consistent hole quality, tight tolerances, and minimal chipping—critical for industries like electronics, automotive, and construction.

Q: How does automatic glass processing improve drilling accuracy?

A: Through features like CNC control systems, online CAD drawing input, and auto tool change systems that reduce human error.

Q: Can I process both large panels and small pieces with one machine?

A: Yes, BLM’s A71X series supports sizes from 800×300mm up to 6000×3000mm with hole diameters from φ6–φ50mm.

Q: Is it possible to integrate drilling machines with other equipment?

A: Absolutely. BLM machines can be used standalone or connected with edging machines, cleaning machines to form an automated production line.

Q: What are the maintenance requirements for high precision glass drilling machines?

A: Machines include automatic lubrication systems and have accessible interfaces for real-time fault detection via alarm signals. Regular maintenance is minimal but essential for peak performance.