Introduction

In modern glass deep processing, glass milling technology plays a decisive role in drilling, slotting, and complex contour shaping. From architectural facades to household appliances, precision requirements continue to rise as glass components become thinner, larger, and more structurally demanding, driving the need for advanced architectural glass processing equipment.

When manufacturers cnc mill glass, machining accuracy is often attributed to programming quality, tooling selection, or operator experience. However, machine temperature remains a widely underestimated systemic variable. Thermal changes influence not only cutting stability but also structural alignment and long-term repeatability.

This issue becomes especially critical in high-consistency applications such as architectural glass, home appliance panels, and shower enclosure glass milling machine production, where even small deviations in hole spacing or edge quality can result in assembly failure or hidden breakage risks.

How Machine Temperature Affects the CNC Glass Milling Process

Sources of Heat During CNC Glass Milling

Heat generation in CNC glass milling is not accidental; it is inherent to the process. High-speed spindle rotation combined with abrasive contact between tools and glass creates continuous frictional heat. In an automated glass production line, long-term continuous operation leads to gradual systemic temperature rise, too.

Thermal Expansion and Structural Deformation of Key Components

All machine structures respond to temperature change. Even microscopic thermal expansion in spindles, crossbeams, or guide rails can alter relative positioning. Over time, these micro-deformations accumulate and directly affect CNC positioning accuracy and repeatability.

In high-precision glass hole drilling or complex milling sequences, small positional deviations amplify across the glass panel. This cumulative effect is especially problematic in high-precision glass drilling and milling, where symmetry and spacing tolerance are tightly controlled.

Ideal Temperature Requirements for High-Precision Glass Milling

Recommended Operating Environment and Stability Standards

Stable ambient temperature reduces drift caused by diurnal and seasonal changes during continuous production.

However, ambient control alone is not sufficient. More critical is the machine’s inherent adaptability to temperature variation. Equipment designed with thermal compensation in CNC machines in mind maintains precision even when environmental conditions are not perfectly controlled.

Why Temperature Stability Is More Important Than Low Temperature

Glass processing is far more sensitive to temperature changes than absolute temperature values. A stable thermal state allows the machine structure to reach equilibrium, preserving dimensional consistency throughout the production cycle.

Unlike metalworking, to cnc mill glass successfully does not allow for easy post-process correction of thermal stress errors. Once drilling or milling deviations occur, downstream processes such as polishing or tempering cannot fully compensate.

Systemic Impact of Machine Temperature on Finished Glass Quality

Initial Offsets in Dimensional Accuracy and Hole Consistency

The first visible symptom of thermal instability is inconsistent hole-to-hole spacing in multi-hole glass panels. While individual deviations may appear negligible, their cumulative effect becomes critical in high-density drilling layouts.

Products with strict assembly tolerances, such as shower enclosure glass, make these offsets immediately visible during installation.

Chain Reactions Affecting Edge Quality and Surface Finish

Misaligned holes or contours introduce localized stress concentration. Even minor contour deviation alters tool engagement and contact pressure, increasing the risk of micro-chipping during milling.

Therefore, edge chipping prevention in glass milling becomes significantly harder when the machine’s thermal state is unstable. Consequently, the burden on subsequent grinding and polishing processes increases, reducing overall efficiency and yield.

Glass Breakage and Hidden Quality Risks

When thermal stress overlaps with mechanical stress, latent micro-fractures may form. These defects are especially dangerous in large-format or ultra-thin glass.

In many cases, breakage does not occur immediately but later during transport, installation, or end use, creating hidden quality risks.

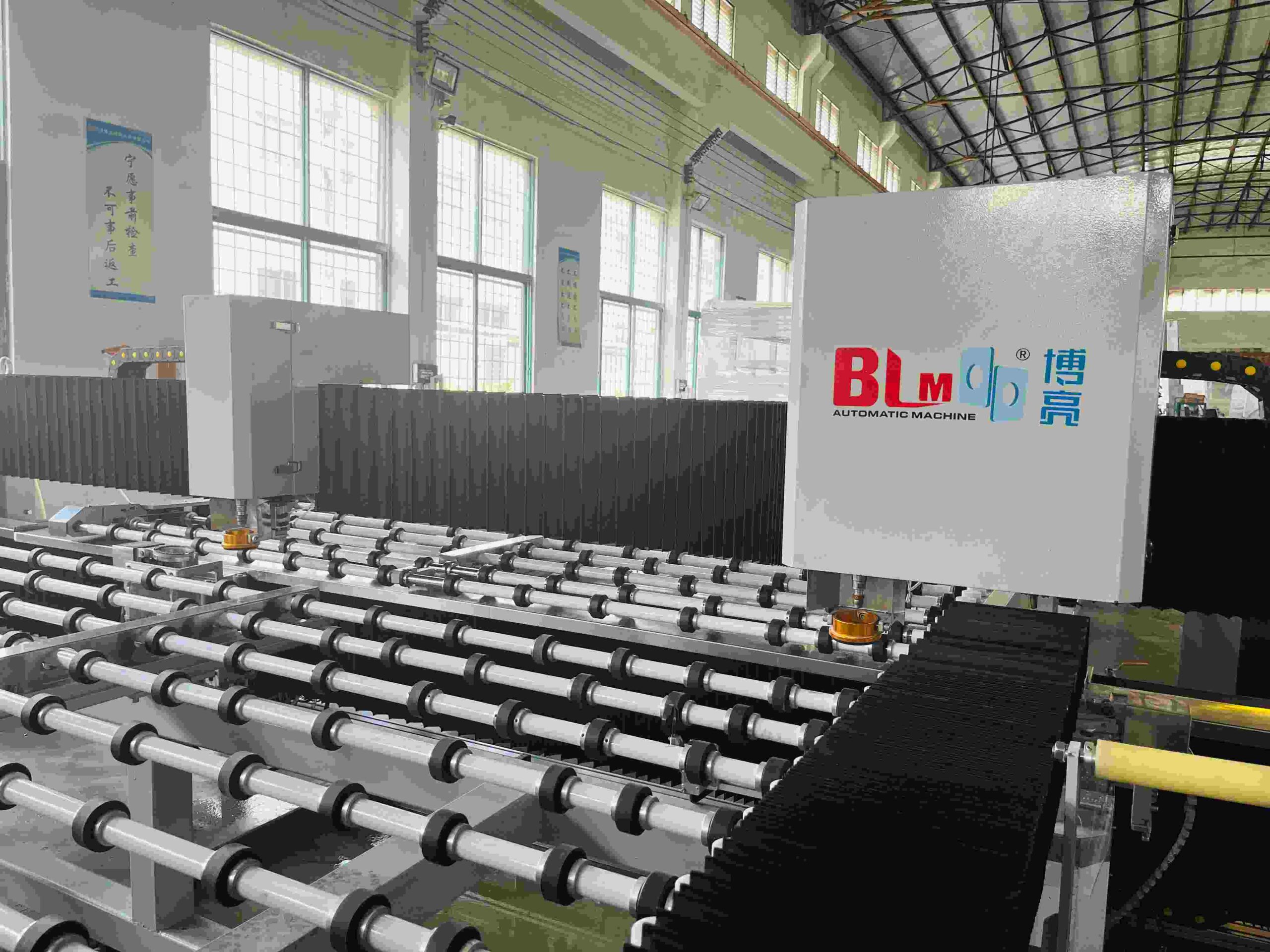

To mitigate these risks, specialized equipment design is required. Below is a comparison of how BLM Automatic Machine’s core models handle high-precision requirements:

| Caractéristique | Glass Drilling & Milling Machine & Polishing Machine A92 | Vertical Drilling & Milling & Polishing Machine A71X |

| Structure | Horizontal Gantry Type | Vertical Space-Saving Design |

| Thermal Strategy | High thermal inertia frame to resist rapid fluctuations. | Natural heat dissipation through vertical coolant drainage. |

| Spindle Specs | High-power water-cooled spindles. | 12,000rpm electric spindle with integrated cooling. |

| Processing Range | Ideal for large-scale batches and home appliances. | Max glass size up to 4200x2500mm (A71X-4225). |

| Core Advantage | Integrated drilling, milling, and polishing in one cycle. | Online barcode reading & ERP integration for auto-positioning. |

Methods of Controlling Machine Temperature in Glass Milling

Cooling System Design Tailored for Glass Milling

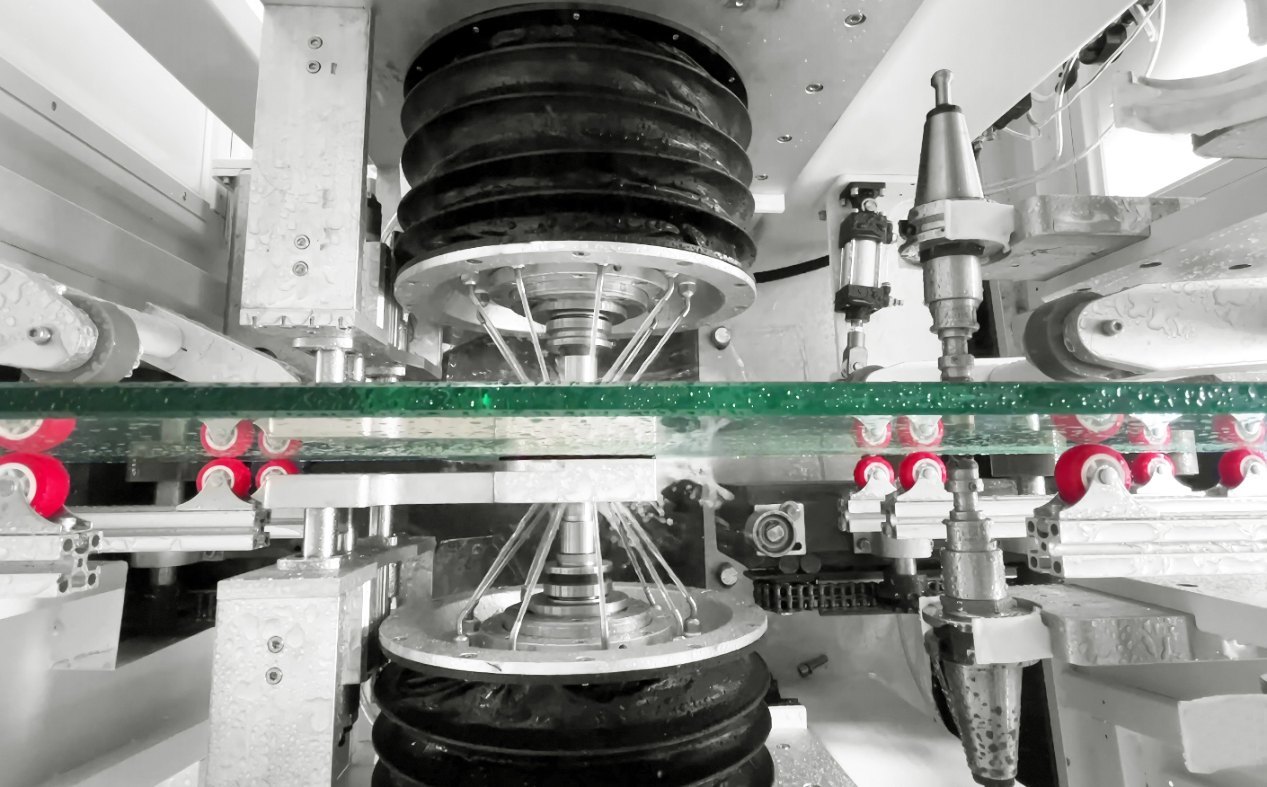

Spindle water-cooling systems play a key role in stabilizing temperature during continuous drilling and milling. Proper coolant flow reduces tool temperature rise and maintains consistent cutting conditions.

For machines with multi-spindle configurations, cooling systems must be matched to the processing rhythm to avoid uneven thermal distribution.

Impact of Equipment Structural Design on Thermal Stability

Machines with gantry-style structures and large-scale frames exhibit higher thermal inertia. This reduces the magnitude of deformation caused by temperature fluctuation.

High-rigidity designs also ensure that thermal expansion occurs uniformly rather than locally, minimizing precision loss.

Systemic Temperature Management Strategies During Processing

Optimizing spindle speed and feed rate helps control heat input. Continuous processing accumulates heat differently than intermittent operation, requiring different management strategies.

Modern automated lines increasingly rely on program logic and system-driven control rather than manual experience to manage temperature-related risks.

Systemic Solutions from an Equipment Supplier Perspective

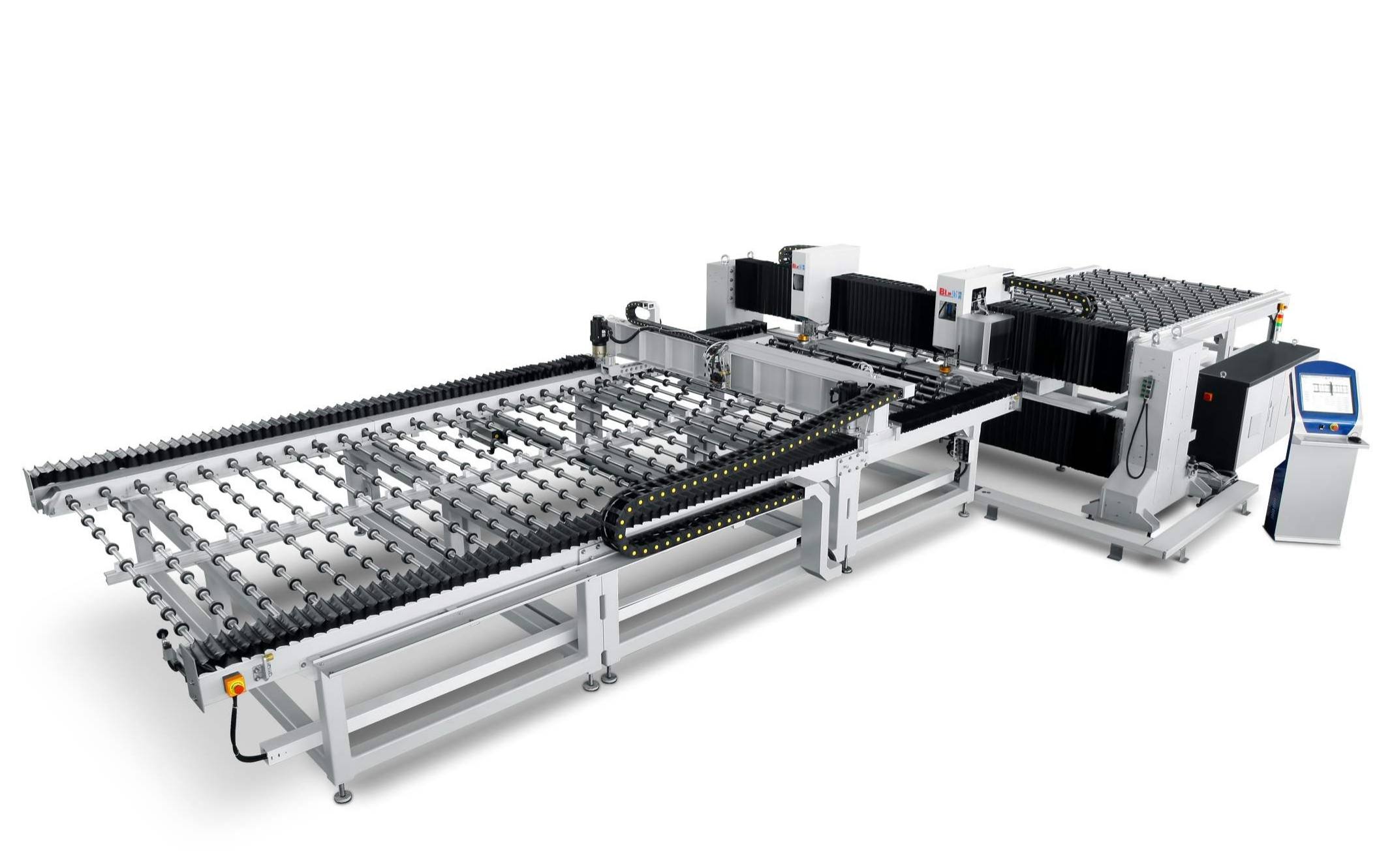

From an equipment design standpoint, thermal stability must be addressed at the system level. For example, Glass Drilling & Milling Machine & Polishing Machine A92 integrates drilling, milling, and polishing in a rigid, large-format structure, reducing cumulative thermal deformation during long production cycles. Its integrated processing approach minimizes intermediate handling, which further stabilizes thermal behavior during architectural and shower enclosure glass milling machine processing.

Similarly, Vertical Drilling & Milling & Polishing Machine A71X adopts a vertical structural layout that improves heat dissipation and maintains positional accuracy when processing large glass panels. Its multi-tool configuration supports stable operation even under extended runtime, making it suitable for high-consistency production lines.

These designs demonstrate how temperature control is embedded into equipment architecture rather than treated as an external fix.

Conclusion

Machine temperature influences CNC glass milling precision through structural deformation, station offsets, and stress accumulation. Its impact extends beyond immediate machining accuracy to long-term product reliability and yield consistency.

For manufacturers seeking stable, high-precision CNC glass milling solutions with long-term thermal reliability, BLM Automatic Machine provides system-level equipment designs that integrate temperature control into every stage of glass deep processing.

FAQ (questions fréquentes)

Q: What type of equipment is better for long-term thermal stability?

A: Machines with rigid frames, optimized cooling, and integrated processing functions are more resistant to thermal deformation over long production cycles.

Q: Can cooling systems fully eliminate thermal deformation?

A: Cooling systems reduce heat accumulation but must work together with structural design and process control to achieve full stability.

Q: How does temperature influence shower enclosure glass milling machine performance?

A: Temperature instability can cause hole spacing errors and edge defects, which are critical in shower glass assembly accuracy.

Q: Why does machine temperature affect CNC glass milling accuracy?

A: Temperature changes cause thermal expansion of machine components, leading to positional deviation and reduced repeatability during drilling and milling.

Q: Is low temperature better for glass milling machines?

A: Not necessarily. Stable temperature is more important than low temperature because glass processing is sensitive to temperature fluctuation.